PRODUCTION

Made in Italy sub-contracted turning

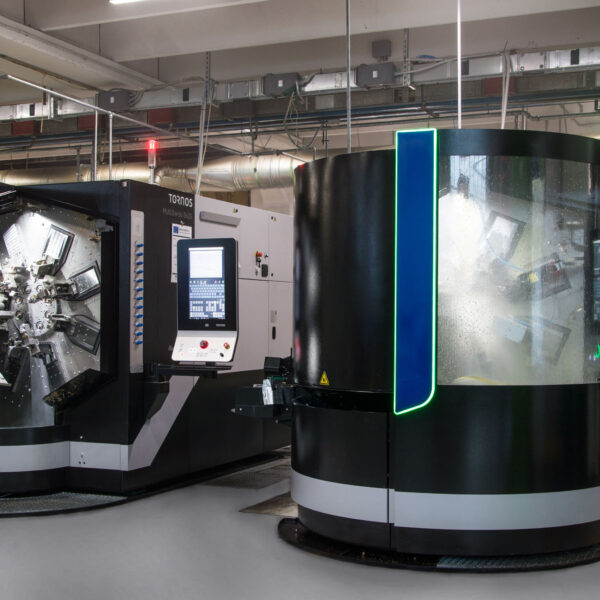

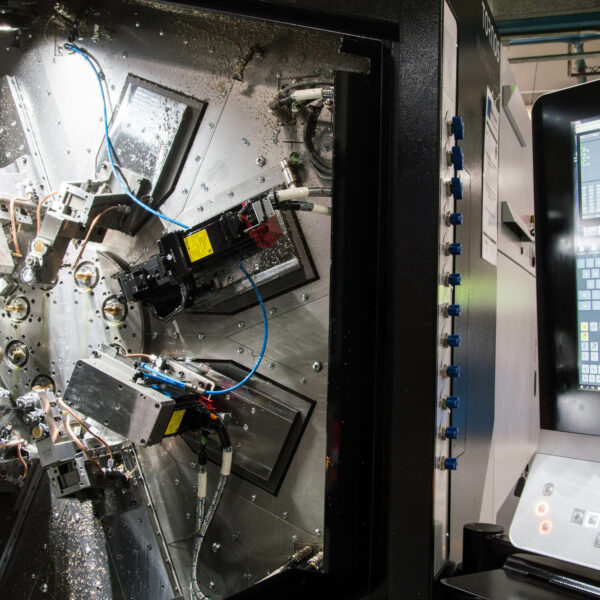

The production department at Torneria Essezeta is equipped with mechanical and CNC multi-spindle automatic lathes (6 and 8 spindles) with an automatic bar loading system.

Processing can be performed on bars with variable geometric cross-section (round, hexagonal, drilled, etc.) and external diameters from 5 mm to 50 mm. Torneria Essezeta also has a mechanical workshop to serve the production departments. The processing of components is carried out on different materials and alloys ranging from brass to aluminium, including standard and special steels. All of this following the tradition of Italian manufacturing that sees us ranked among the best in the world for quality and precision.

SUSTAINABILITY, ENVIRONMENT, EFFICIENCY AND QUALITY

Turnery production, for the entire supply chain, is managed according to principles of sustainability, respect for the environment, efficiency and quality.

For example, the handling of the resulting chips, which in turn are destined for regeneration, takes place in a fully automatic manner, up to the storage silos, after centrifugation to recover the coolant oil. The advanced washing system is also carried out in absolute compliance with environmental standards, guaranteeing a finished product that is degreased and free from production residues. This too, like everything else, takes place under the sign of efficiency and sustainability. This is also thanks to a comprehensive quality policy, defined according to the guidelines of the UNI EN ISO 9001:2015 standard and its related certification in our possession.

State-of-the-art machinery and lathes

Torneria Essezeta has a machinery range that is up to the most modern industrial turning challenges.

Attention to detail, quality of materials, delivery times: over the years we have consolidated our experience and know-how in order to offer manufacturing standards that always meet expectations. A mission that we support with strength and determination every day, as we are certain that it is not just numbers or machinery that make the difference, but also and above all commitment, passion and perseverance. Today, Torneria Essezeta is the ideal strategic partner for sub-contracted turning operations: a guarantee in terms of professionalism and availability for entrepreneurs and companies wishing to have a qualified collaborator at their side at all times.

PRECISION TURNING WITH ADVANCED MACHINERY

The suppliers of products, materials and services for our turning company are qualified in accordance with strict internal procedures, without neglecting the traditional management of business relations, which has always been carried out with a continuous daily comparison, interacting with both the sales managers and the respective technical departments in order to seek increasingly advanced solutions in the manufacture of special tools, optimisation of the choice of raw materials or auxiliary materials for production.

CONTACT US WITHOUT COMMITMENT

Online or on the phone we are ready to answer you.

Our sales department is ready to respond to your requests and provide you with a no-obligation personalized quotation. Fill out the contact form and send us your technical drawings to receive a quick quote.